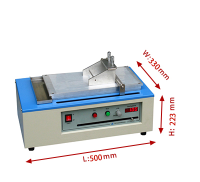

MSK-AFA-I Compact Tape Casting Film Coater With Vacuum Chuck 300mm×150mm

MSK-AFA-I Automatic Coater is widely used in various high-temperature coating research, such as ceramic films, crystal films, battery material films, special nano films, and can adapt to future development of film-forming technology under high temperature conditions. The substrate is fixed by means of vacuum adsorption, so that there is no wrinkle phenomenon on the substrate during the coating process, and the coating is even smoother. The width of the film remain unchanged, and the film thickness can be adjusted according to the micrometer above the doctor blade.

Specifications

|

Product Name

|

MSK-AFA-I Automatic Coater

|

|

Product Model

|

MSK-AFA-I

|

|

Installation Conditions

|

This equipment is required to be used at an altitude of 1000m or less, a temperature of 25℃±15℃, and a humidity of 55%Rh±10%Rh.

1. Water: N/A

2. Electricity: AC220V 50Hz, must have good grounding

3. gas: N/A

4. Workbench: size 800mm×600mm×700mm, bearing more than 200kg

5. Ventilation device: no need

|

|

Main Parameters

(specification)

|

1. Power supply: AC 220V, 50HZ

2. Total power: 50W

3. Coating speed: 10mm/s-100mm/s adjustable

4. Coating travel distance: 10mm-290mm

5. Vacuum aluminum plate / chuck: 360mm×200mm (length×width)

6. Vacuum size (max): 300×150mm (length×width)

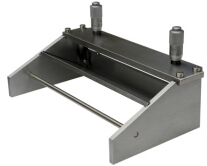

7. Film applicator: 150mm micron adjustable type (other sizes can be selected), the adjustable range is 0.01mm-5mm

8. Film thickness accuracy: ±0.01mm

|

|

Product Dimension and Weight

|

Dimension: 500mm×330mm×223mm

Weight: 50kg

|

Sheet Film Coater w/ Vacuum Chuck ( 300Wx600L mm) & 250mm Doctor Blade - MSK-AFA-II-VC

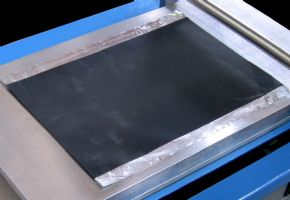

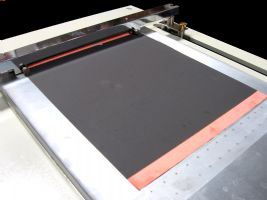

MSK-AFA-II-VC is a Large Automatic Film Coater with a Vacuum chuck ( 300 mm W x 600mm L) designed to produce films with consistent thickness by using thickness adjustable applicators. It has a unique driving system to produce a smooth coating on all types of materials. The vacuum chuck is built in to hold the substrate sheet in place, which is particularly useful when coating on the thin substrate and making uniform tape casting. One 250 mm width gap adjustable applicator is included. This machine can be used for research on SOFC and Li-Ion battery electrode coating.

Specifications

Working Voltage

|

INPUT: 24VDC

One UL/CSA listed 100-240VAC IN - 24VDC OUT power adapter is included. |

| Max. Power Consumption |

100W |

Traverse Speed |

- 5 - 100 mm/sec variable

- Accuracy: 10mm/sec

|

| Stroke Length |

- 10 - 550 mm adjustable by using the Adjustable Position Switch

|

| Max. Coating Dimensions |

|

| Vacuum chuck |

- Vacuum chuck made of Aluminum alloy with < 1 mm holes. The hole distance is around 14.8 mm.

|

Vacuum Pump (Optional)

(Remove the oilless pump from the standard pack Since 02/26/2016 ) |

- 120L/min Oilless Vacuum Pump

|

Film Applicator

|

|

| Dimensions |

- Vacuum Chuck : 600mm(L) x 300mm(W)

- Product: 805mm(L) x 430mm(W) x 223mm(H)

Click the pic for more detail. Click the pic for more detail. |

| Compliance |

- CE certified

- NRTL / CSA certification is available upon request at an extra cost.

|

| Warranty |

One year limited warranty with lifetime support |

Application Notes |

- Pic.1 and 2 show coated cathode and anode for Li-Ion batteries. Please click here to see how to

- It is recommended to operate the coater under a fume hood. (Click Pic.3 for detail.)

- You need a vacuum mixer to make uniform coatings (Click Pic.4 for detail.)

- You may need a Slurry Viscosity Tester to make coatings consistent (Click Pic.5 for detail.)

- You may need a vacuum oven to dry the films and remove the binder after coating. (Click Pic.6 for detail.)

- Rolling pressing is necessary to ensure good density and adhesion of electrode materials to the current collector substrate after coating. Please select a rolling press from here. (Click Pic.7 for detail.)

Pic.1 Pic.2 Pic.3 Pic.4 Pic.5 Pic.6 Pic.7 |

| Net Weight |

30 kg (67 lbs) |

| Shipping Dimensions |

48"(L) x 40"(W) x 37"(H) |

| Shipping Weight |

255 lbs |

STANDARD PACKAGE

Compact Tape Casting Coater w/ Vac. Chuck (200Wx365L mm) & Film Applicator & Optional Heater - MSK-AFA-III

MSK-AFA-III is a compact tape-casting coater with various heating designed to produce films with consistent thickness. It has a unique driving system to produce a smooth coating on all types of materials. The flat vacuum chuck is built in to hold the substrate sheet in place. One 100 mm width adjustable micrometer applicator (doctor-blade). The heating plate with the digital controller either on top or bottom is optional for drying up to 100°C with +/-1°C temperature accuracy. This equipment can be used by researchers on ceramic tape castings and Li-Ion battery electrode coating.

Specifications:

| Model |

MSK-AFA-I

|

MSK-AFA-III-HB

|

MSK-AFA-III-110/220

|

MSK-AFA-III-HB

-UV-110/220

|

MSK-AFA-IIIT-HBT

|

| Optional Heating Cover Voltage and Power |

No Heating

|

Bottom Heating 110/ 220VAC 850W 120ºC

|

Top Heating

1.2KW, 100ºC

|

Top UV (WL: 365nm)

Bottom Heating, 1kW, 120ºC

|

Top and Bottom Heating

110/220V, 2.3 kW, 120ºC

|

| Working Power |

- Power adaptor: Input 100-240VAC, Output 24VDC

|

| Traverse Speed |

- 10 - 100 mm/sec variable

- Accuracy: ± 5-10 mm/sec

|

| Coating Area |

- Standard Package: 320mm(L) x 100mm(W) due to the width and occupied area of the 100mm applicator

- Suggested Maximum: 350mm(L) x 180mm(W) Reduced width to avoid slurry spilling off the vacuum bed

- Length 10 - 350 mm adjustable by using Adjustable Position Switch

|

Vacuum Chuck |

- Vacuum chuck made of Aluminum alloy with < 1.0 mm hole

- Vacuum Chuck Dimensions: 365mm(L) x 200mm(W) ( 14“L x 8"W )

- Note: You may order a glass plate to coat slurry on a porous substrate at the link below

|

| Coating Area |

- Maximum: 350mm(L) x 180mm(W) Reduced width to avoid slurry spilling off the vacuum bed

- Length 10 - 350 mm adjustable by using Adjustable Position Switch

|

Film Applicator

|

Note: Thinnest film that can be achieved is > 10 microns Note: Thinnest film that can be achieved is > 10 microns |

Vacuum Pump

(optional) (optional) |

|

| Pump connector |

- The vacuum control power switch is located on the front panel, and the power plug ( female ) is built into the back of the machine to connect an optional vacuum pump

- The pump connector is a compression-type 8mm O.D tube fitting which is located on the back panel (see pic below). An 8mm Dia. x 4ft polyurethane tube is included

|

Heating Cover(Optional) |

- Pre-installed on the top cover

- Built-in digital temperature controller with an accuracy of +/-1°C

- Suspension support helps open the cover easily and safely

- Max. Heating Temp.: 100°C

- Note: In order for faster and uniform heating, please preheated the vacuum chunk to 60- 70°C before coating, and keep heating during coating, then close the cover and increase the temperature to ~100°C after coating

|

| Product Dimensions |

For MSK-AFA-I (without Dryer Cover)

550 (L) x 330 (W) x 150 (H), mm |

For MSK-AFA-III (with Top heater)

550mm(L) x 330mm(W) x 320mm(H) |

Compliance

|

- CE Certificate

- NRTL or CSA certification is available upon request

|

| Warranty |

One-Year limited warranty with lifetime support |

| Application Notes |

|

| Net Weight |

45 kg (96 lbs) |

60 kg (135 lbs) |

| Shipping Weight & Dimension |

160 lbs, 40" x 30" x 30" |