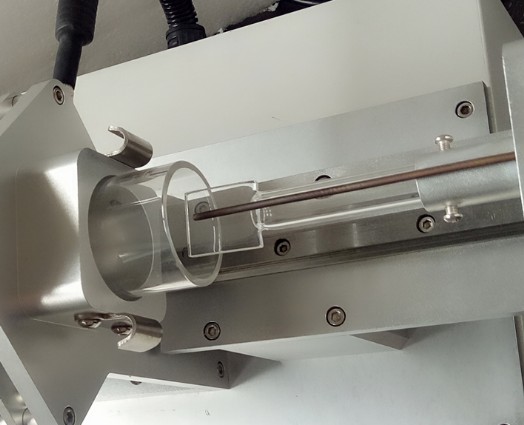

1.1'' Mini RTP 1200 degree Tube Furnace with Halogen Tube

The RTP1000S small rapid annealing furnace is an integrated instrument with clever structural design and unique heating method, which greatly reduces the volume and power, while increasing the temperature rise and fall rate several times compared to traditional annealing furnaces. It can both create an atmosphere and vacuum, meeting the process requirements of many users for rapid annealing of small samples.

APPLICATION

1.Fast Annealing,Post-ion implantation annealing

2.RTO,RTN

3.Silicidation

4.Diffusion

5.Electrode alloying

6.Crystallization and densification

Specifications

| Product Name |

Mini RTP Tube Furnace |

| Model |

Mini-RTP |

| Furnace Type |

Fast Heating/Cooling Sintering |

| Display Model |

LED Digital Light |

| Maximum Temperature |

1100℃ |

| Working Temperature |

≤1000℃ |

| Heating rate |

≤20℃/Second |

| Heating zones |

Single heating zone |

| Quartz Tube Diameter |

O.D50*600mm |

| Inner Diameter |

I.D 42*600mm |

| Heating Zone Length |

100mm |

| Max Sample |

35*25mm

|

| Control mode |

Intelligent PID auto control |

| Temperature Accuracy |

±1℃ |

| Temperature curve |

30 segments programmable |

| Over heat alarm |

Have |

| Overcurrent protection |

Have |

| Thermocouple Failure Protection |

Have |

| Temperature Sensor |

K-type thermocouple |

| Heating Element |

3pieces Infrared tube |

| Quartz Tube Material |

High Purity Quartz |

| After-sales service |

12 month warranty, durable maintaince and repair support |

| Power Supply |

220V 50HZ |

| Rated power |

1.5kw |

| Overall dimensions |

610×400×410 (mm ) |

| Packing |

3-ply wooden case |

| Accessories |

Protective Glove,Crucible Tong,Crucible,Quartz Tube,Vacuum Flange,User Manual. |

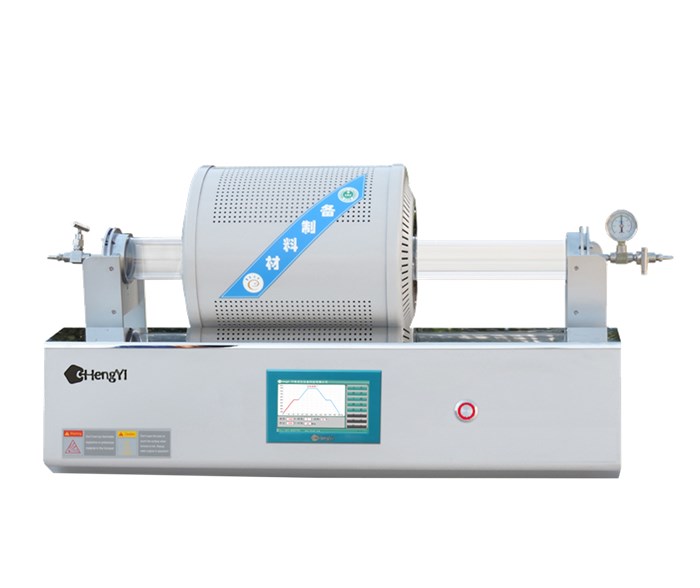

2''3''Chamber Movable 1200 degree Tube Furnace with OD60mm /OD80mmQuartz Tube

This device is mainly used in the field of rapid temperature rise and fall. The furnace can automatically move left and right according to the set requirements, and the movement speed can be manually adjusted. After the furnace heats up to the set temperature on one side, it directly moves to the sample heating zone on the other side to achieve rapid heating, up to 140 ℃/min. After sintering, the furnace moves away from the sample heating zone to achieve rapid cooling. Before 300 ℃, the cooling rate can reach 200-50 ℃/min. The furnace can automatically move back and forth to complete the thermal fatigue test of the material!

Specification:

| Product Name |

1200 Degree CMT Tube Furnace |

| Model |

CMT1200 |

| Furnace Type |

Fast Heating/Cooling Sintering |

| Display Model |

LCD Touch Panel |

| Maximum Temperature |

1150℃ |

| Working Temperature |

≤1100℃ |

| Heating rate |

≤20℃/Second |

| Heating zones |

Single heating zone |

| Quartz Tube Diameter |

O.D60*1000mm O.D80*1000mm |

| Inner Diameter |

I.D 54*1000mm I.D 74*1000mm |

| Heating Zone Length |

220mm |

| Control mode |

Intelligent PID auto control |

| Temperature Accuracy |

±1℃ |

| Temperature curve |

30 segments programmable |

| Over heat alarm |

Have |

| Overcurrent protection |

Have |

| Thermocouple Failure Protection |

Have |

| Temperature Sensor |

K-type thermocouple |

| Heating Element |

Fe-Cr-Al Alloy doped by Mo |

| Quartz Tube Material |

High Purity Quartz |

| After-sales service |

12 month warranty, durable maintaince and repair support |

| Power Supply |

220V 50HZ |

| Rated power |

12kw |

| Overall dimensions |

1120×640×520 (mm ) |

| Packing |

3-ply wooden case |

| Accessories |

Protective Glove,Crucible Tong,Crucible,Quartz Tube,Vacuum Flange,User Manual.

|

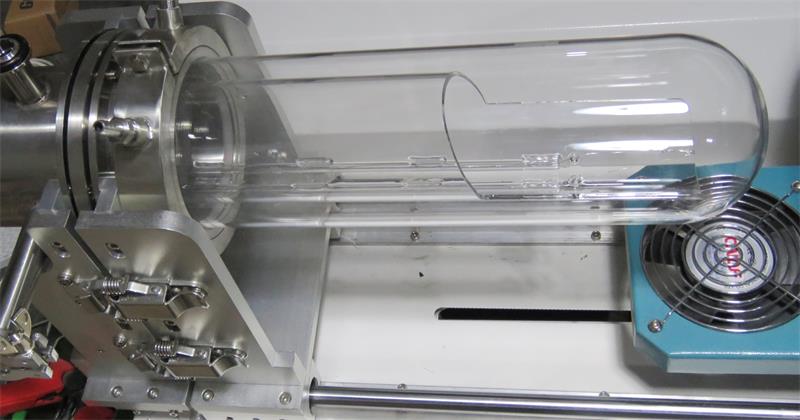

CHY-RTP1100 1200 Degree 4" RTP Tube Furnace System with O.D100mm Quartz Tube

1200 degree Rapid Thermal Processing Furnace, abbreviated as RTP (Rapid Thermal Processing Furnace), not only has a fast heating rate of 100 ℃/S, but also a qualitative leap in cooling rate, with a cooling rate of 100 ℃/S. Our engineers cleverly utilized the cold wall process to achieve such a fast cooling rate. Real rapid heating and cooling! The cavity adopts a unique double-layer quartz tube structure, with the outer tube inlet and the inner tube outlet, allowing the reaction atmosphere to come into full and uniform contact with the processed sample. The reason why heating lamps can quickly heat up silicon wafers is because the wavelength of the light source is between 0.3 and 4 microns, and the quartz tube wall cannot effectively absorb the radiation in this band, while the wafer is the opposite. Therefore, the wafer can absorb radiation energy and quickly heat up, while the quartz tube wall still maintains low temperature, which is known as the cold wall process.

Specifications

| Product Name |

1200 Degree RTP Tube Furnace |

| Model |

RTP1100 |

| Furnace Type |

Fast Heating/Cooling Sintering |

| Display Model |

LCD Touch Panel |

| Maximum Temperature |

1150℃ |

| Working Temperature |

≤1100℃ |

| Heating rate |

≤100℃/Second |

| Heating zones |

Single heating zone |

| Quartz Tube Diameter |

O.D100*1000mm |

| Inner Diameter |

I.D 94*1000mm |

| Heating Zone Length |

220mm |

| Control mode |

Intelligent PID auto control |

| Temperature Accuracy |

±1℃ |

| Temperature curve |

30 segments programmable |

| Over heat alarm |

Have |

| Overcurrent protection |

Have |

| Thermocouple Failure Protection |

Have |

| Temperature Sensor |

K-type thermocouple |

| Heating Element |

12 pieces Infrared tube

|

| Quartz Tube Material |

Double Layer High Purity Quartz

|

| After-sales service |

12 month warranty, durable maintaince and repair support |

| Power Supply |

220V 50HZ |

| Rated power |

12kw |

| Overall dimensions |

800×540×750 (mm ) |

| Packing |

3-ply wooden case |

| Accessories |

Protective Glove,Crucible Tong,Crucible,Quartz Tube,Vacuum Flange,User Manual. |

APPLICATION

1.Laboratory heat thermal processing

2.High Vacuum Sintering Heating Annealing Brazing

3.Laboratory Thin Film Preparation,Nano tube growthing

4.Laboratory CVD system,graphene growthing,preparation.

5.Fast Heating/Cooling Sintering