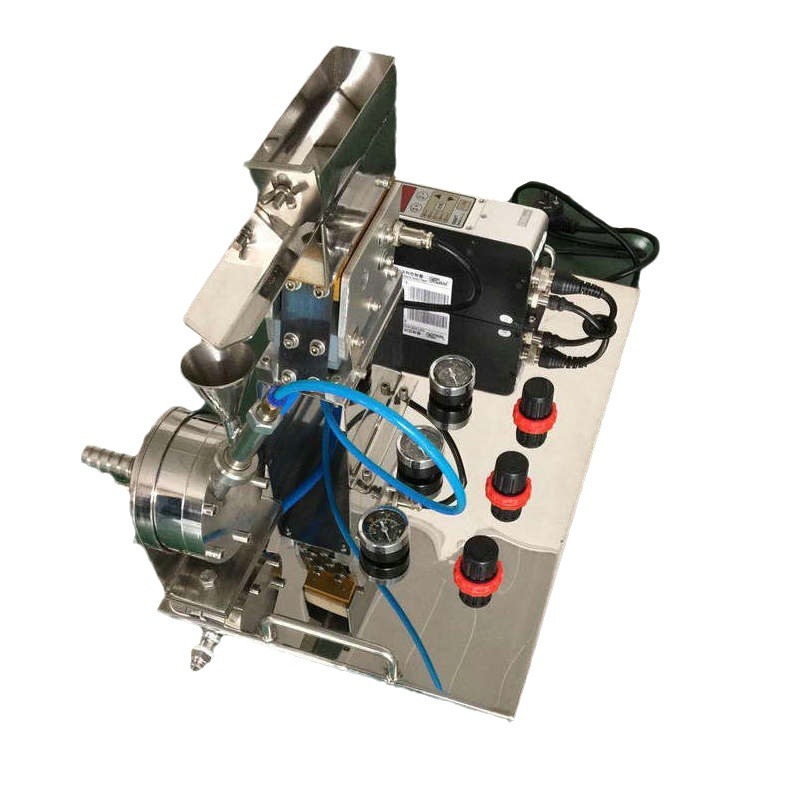

Compact Jet Mill with High-Efficiency Cyclone, Speed 50 - 500 g/hr - MSK- BPM-50

MSK-BPM-50 is a lab-scale jet mill for materials with various hardness and properties. It grinds materials such as ceramic, magnet, ferrite, and metallic alloy into micron-scale powder (2-5 microns) with an output rate of 50 - 500g/hr.

The jet mill grinds with a high-speed jet of compressed air or inert gas to collide the particles with each other. It is capable of outputting particles with the right size while continuing milling particles above the desired size. Therefore, the ground product comes in narrow size distribution and good uniformity. Particles are separated from the gas stream by cyclonic separation.

SPECIFICATIONS

| Working Power |

- 110 - 240V AC, 50/60Hz

- 350 W

|

Required Air Pressure

|

- Recommended 0.6 - 1.0 MPa Pressure [Please keep the Feeding Pressure > Crushing Pressure. For example: Total pressure=0.8 MPa, Feeding Pressure=0.45 MPa, Crushing Pressure=0.35 MPa].

- Recommended gas consumption rate: 0.25 - 0.5 m3/ minute

- An air compressor is required but is NOT included. (Please order one from a local store )

|

| Particle |

- Input: 100 - 200 mesh [150-750 um]

- Output: 2 - 15 micron, 50-500g/hr

- The output particle size is depended on material hardness and input particle size. Coarse particles may need 3-5 times milling to obtain the finest size.

|

Particle collecting

|

- One output particle collecting bag is included

|

High-Efficiency Cyclone

|

- A lab-scale cyclone system is connected to the jet mill with a filter to collect fine powder easily

- Estimated collection efficiency: 85% ~ 90%

- Collection bottle valume: 500 ml

- For fine particle, you may need multi-cyclones coonected together

|

| Optional |

- A pre-crushing may be needed to achieve finer particles during jet milling ( Click pic. 1 to order )

- An optional sieve can be used to filter the sample to 100-200 mesh to meet the input requirements. Please click the picture (Pic.2) to order the MSK-SYU-3 sieving system

Pic. 1 Pic. 1  Pic. 2 Pic. 2 |

| Mill Liner |

- High purity fully sintered alumina

|

| Powder Feeder |

- Automatic powder feeder controlled by vibration frequency

- Frequency: 40-400Hz adjustable

|

| Net Weight |

|

| Shipping Weight & Dimensions |

|

| Dimensions |

|

| Warranty |

One year limited warranty with lifetime technical support |

AO Desktop Micro laboratory Small low temperature Jet Mill 0.5-300g / h

The machine set feeding, crushing, receiving, control as one of the ultra-micro crushing experimental unit, at the same time, its small volume is also easy to carry. Suitable for fine chemicals, medicine, pigments, pesticides, minerals and other high-tech materials industry.

2. Features ① The machine is made of stainless steel SUS304 material, and the internal contact material part is made of alumina corundum ceramics, no pollutant material, to ensure the high purity of the crushing material.

② Demolition, installation, cleaning is more convenient, users can frequently replace the crushing varieties.

③ Microcomputer high recovery rate, suitable for laboratory or ultra-small, high value material crushing use.

④ The overall design is exquisite

Technical parameter

|

working power supply

|

· 208 - 240V AC 50/60Hz

· 5000 W

|

|

Pressure required

|

· 0.6 Mpa

· Gas consumption: 0.5 m3 / minute

· High pressure and inert gas can be used to powder some oxygen-sensitive materials or flammable and explosive materials

|

|

fineness

|

· Parularity: 2-5 um

· Quantity quantity: 0.5-300g / hr

|

|

net weight

|

15 kg

|

|

size

|

480 L x 320 W x 350 H (mm)

|

|

guarantee period

|

One-year warranty period, lifetime maintenance

|