|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Desktop Precision Diamond Wire Saw

|

|

| Model No.︰ | STX-202A |

| Brand Name︰ | MTI |

| Unit Price︰ | US $ 5886 / pc |

| Minimum Order︰ | 1 pc |

|

|

|

|

|

|

|

|

Desktop Precision Diamond Wire Saw With Touch Screen Control - STX-202A

STX-202A is a small precision diamond wire saw for cutting sample ≤ 2" diameter or square up to 50mm in thickness. It is designed to provide smooth cutting for many kinds of materials, especially for fragile crystals and TEM or IC samples by using a 0.28mm diameter x 15-meter long diamond impregnated wire. It is an ideal cutting tool for material research, TEM sample preparation, and IC failure analysis.

SPECIFICATION:

| Power |

- Wire Saw Control Unit: Universal 110V to 240VAC, 50/60Hz, 200W max.

|

Structure

|

- Heavy-duty aluminum alloy structure with compact size

- automatically controlled Y-axis by the digital panel

- single wire swing cutting with adjustable wire length from 5-15mm (broken wire still can be used)

- Transparent plastic plates are included to prevent Coolant splashing

- Add an oil refill cup behind the forming tube, please apply 10-15 drops Anti-Wear Oil before first-time use

- Wire spooler motor, 3 Amps, Torque = 1.8Nm

|

Sample Stage

|

- Z-axis: 50mm, automatically controlled by the digital panel

- Y-axis: 50mm, automatically controlled by the digital panel

- Two-dimension sample stage built-in 360° degree horizontal rotating and +/-10° tilting via manual operation

|

Cutting Parameters

|

- Feed Speed: 0.01 mm/min to 40 mm/min adjustable

- Back Speed: 1 mm/min to 100 mm/min adjustable

- Spooler spin speed: 1-260 RPM adjustable

- Cutting depth: 0.1 - 50mm

- Positional accuracy: +/- 0.01 mm

- Please click the picture left to see the samples cut by this machine

|

| Meteorite Sample |

- Please click the picture below to view the meteorite samples that were cut by our wire saws.

Fig. 2 Fig. 2  Fig. 3 Fig. 3  Fig. 4 Fig. 4

|

Controller & Touch Screen |

- Color touchscreen controller will setup wire travel speed, cutting speed and slicing width

|

Diamond Wire |

- ≤ 15 meters used for each installation

- One spool of 0.35mm Dia x 20 meters length Diamond Wire is included for immediate use

- A Diamond Blade Dressing Stone is included for keeping the wire sharp

- Optional:

- For slicing or dicing very brittle crystal, you may order 0.125mm Dia. Diamond Wire. Note that 0.125mm Dia. The wire is very easy to break, please reduce the feeding rate to the minimum. Click the picture below to order spare diamond wires

-

|

Wire Tension System

|

- Standard: steel spring wire tension system with break wire alarm is included

|

Coolant Pump |

- One water pump is included for cooling diamond wire during cutting

- You must use anti-corrosive oil or radiator water as coolant (could buy from any auto store)

- Warning: must clean the machine after each cutting, especially using tap water as the coolant to prevent rust

|

| Optional |

- Swing & Rotation Sample Fixture: Such fixture needs an independent controller for its parameter settings such as swing frequency/ angle (±23°, up to 20 swings/min), rotating speed, and rounds (30rpm max.) Higher cutting surface quality can be expected by swinging or rotating the specimen throughout the cutting process. Please click Pic.2 &3 and video to learn more details. The fixture will enhance cutting speed up to 2 times

Pic.1 Gif.1 Pic.2 Pic.3 Video |

Product Dimensions

|

- Saw: 414mm(L) x 500mm(W) x 750mm(H)

- Controller: 340mm(L) x 290mm(W) x 170mm(H) (click to enlarge the left picture for size detail)

|

| Shipping Dimensions |

48"(L) x 40"W) x 45" (H) |

| Shipping Weight |

220 lbs |

| Warranty |

One year limited with lifetime support, not including cutting wire |

| Certificate |

CE certified. With an additional certification fee, MTI can arrange NRTL to perform UL/CSA inspection and label the machine per customer's request. |

Application Notes

|

- The flow rate of the coolant is adjustable by the valve in the blue feeding tubing. Please adjust it properly to improving cutting performance

- Please use the correct cutting fluid. Don't use tap water

- Must clean the machine after each use

- The wire saw can be placed inside the glovebox with N2 gas via feedthrough at an extra cost

|

| Warnings |

- It is required to use proper cutting fluid with the saw to prevent corrosion of the machine components. We strongly recommend you use an oil-based coolant or lube cool lubricant with the water. Do not use tap water directly, the rust component is not part of the warranty.

- Do not overflush the sample stage, it may rust the Z-axis step motor.

- It is required to apply 10-15 drops Anti-Wear Hydraulic Oil (ISO 32) using an oil can(#19) before first-time use or continue working for 150 hours.

- And a limited amount of grease (general purpose grease will do) should be added to the motor shaft periodically,

- Never cut any materials without the use of proper cutting fluid. If you do so, serious damages can be caused by the spooler driving mechanism.

- For cutting the sticky materials such as non-ferrous alloy, epoxy, and plastic, you must sharpen diamond wire frequently. We suggest that cutting sample along with the included dressing stone (Glue sample and the dressing stone side by side and cut them together, this process will help keep the wire sharp enough for efficient cutting.

- Please clean the machine after the completion of each use.

|

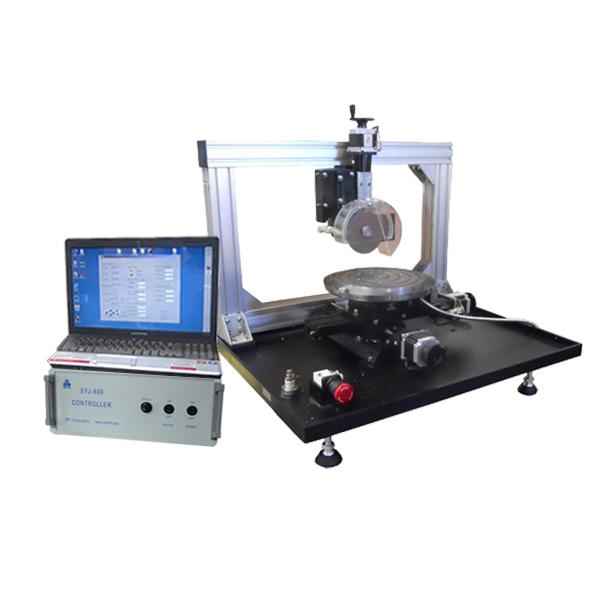

Precision CNC Dicing / Dicing Saw with Digital Controller and Complete Accessories - SYJ-800

SYJ-800 is a dicing saw, designed for dicing and cutting almost all kinds of materials up to 8" diameter wafer or 8" L x 8" W x 1" H components. The SYJ-800 saw can be programmable by computer with position accuracy of 0.01 mm in X, Y, Z, R four dimensions and the sample stage can be rotated by an electric motor to cut sample at any angle with +/- 0.5° tolerance. It is an excellent tool for dicing Al2O3 ceramic sheets and Si or Ge wafers for electronic substrates and solar power panels.

SPECIFICATIONS

| Voltage |

AC 220V (AC 110V 50/60Hz is available with ordering a 500W transformer) |

| Motor |

1/2 HP high torque DC motor with 0 - 3000 RPM |

Effective Dicing Range

|

- Dicing Area : X-axis: 8", Y-axis: 8"

- Dicing Depth: depended on cutting blade diameter:

- 4" Blade's Max. dicing depth <= 2 mm

- 6" Blade's Max. dicing depth <= 20 mm

- If sample area <= 2"x 2", cutting depth can reach Max. 2" by 6" blade and suitable flange

- Rotation: 180° by the motor (rotate speed/degree programmable)

|

| Moving/Cutting Speed Range |

X-axis: 1-50mm/min adjustable

Y-axis: 1-50mm/min adjustable

Z-axis: 1-20mm/min adjustable |

| Rotation Speed Range |

Max. 120°/min |

| Accuracy |

0.0025 mm moving resolution and +/- 0.01 mm position accuracy. |

Dicing Blades

|

Two diamond blades are included:

1 1  2 2  3 3  4 4  5 5 |

PC software

|

- Laptop and PC software is provided with the equipment

- Cutting parameters can be set in the software such as cutting length, width, time, feed speed, kerf loss, etc. Rotation is controlled independently

- Manual or programmable control mode

- compatible with Win 7/8/8.1

- Click the pic left to view the software interface

|

Sample Stage and Holder |

One 220mm diameter glass sample plate and 8" vacuum chuck are included

(The glass sample plate has a flat surface which can be soaked and hold in position by a vacuum chuck. Also, the glass plate can prevent the vacuum chuck from being damaged by the saw blade during the cutting process.)

|

Water Cooling

|

Assemblies of water jetting, draining, and splashing protection is included.

The optional EQ-ECO-430 Coolant Circulating Tank is NOT included, please click the link to order if needed. |

| Net Weight |

90 kg |

| Shipping Weight |

290 lbs |

Dimensions

|

Machine: 734 x 564 x 710 mm

Control box: 340 x 260 x 190 mm |

| Shipping Dimension |

55'' x 39" x 44" |

| Warranty |

One year limited with lifetime support --- including all electronic and mechanical parts. Damaged parts caused by misuse: such as rusted parts from inadequate storage and broken parts by the user are not covered by the standard warranty. |

| Certification |

CE Certified. With an additional certification fee, MTI can arrange NRTL to perform UL/CSA inspection and label the machine per customer's request. |

| Application Notes |

Instruction for SYJ-400 & SYJ-800 turning off windows automatic update

Applications on various materials

For cutting the sticky materials such as non-ferrous alloy, epoxy, and plastic, we must sharp diamond blade open, or cut sample along with the included dressing stone (Glue sample and the dressing stone side by side and cut them together, which will help keep the blade sharp enough for efficient cutting.)

|

|

|

|

|

Product Image

|

|

|

Related Products

|

|

|

|

|

|

|

|

|